High-performance stainless steel powders for sintered components

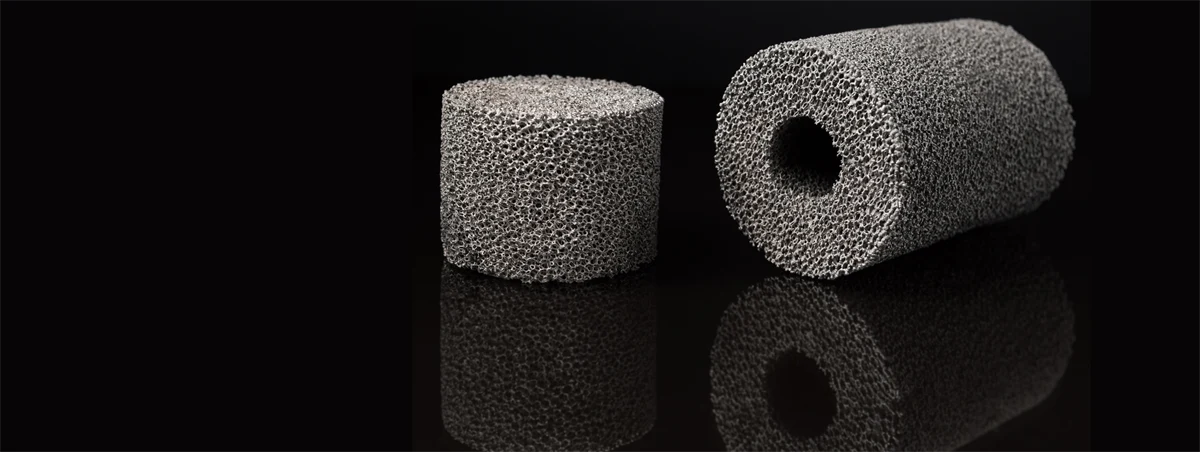

Sintered metal filters

4 key questions about powders for sintered metal filters

If you are a manufacturer of sintered metal filters, the quality and properties of the metal powder you use are absolutely critical for producing high-performance sintered filters. Here are four key questions you would want to ask your metal powder supplier.

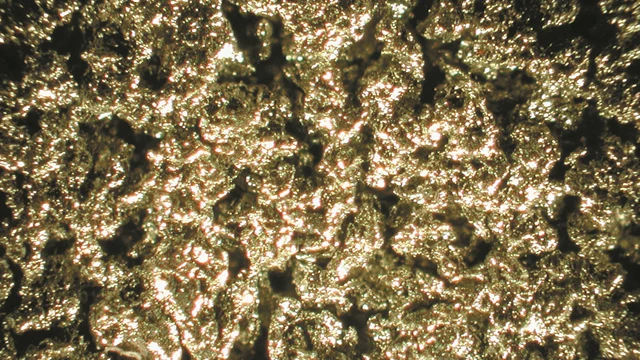

What is the particle size distribution (PSD), shape and morphology?

Morphology, particle size and the sieve cuts influence pore size, strength and permeability. The PSD should also be tailored so that you can achieve your target porosity and filtration grade combined with efficient manufacturing processes.

Höganäs provides metal powders specifically engineered for sintered metal filter applications, with precisely controlled PSD to ensure predictable porosity and filtration efficiency. Depending on the filter grade and sintered filter application, our powders are available in a range of customised sieve cut profiles, typically from a few microns up to close to one millimetre, to match filtration requirements.

When it comes to morphology, our powders are specifically engineered to obtain very irregular shapes, optimised to create excellent green strength to reduce scrap and to enable efficient sintering.

How consistent is the metal powder, batch to batch?

Every Höganäs batch is produced under strict process controls, with full traceability and compliant to ISO 9001/14001 certifications. We work closely with our customers to fine-tune PSD and morphology for optimal sintering behaviour and sinter filter performance in demanding industries such as chemical processing, food & beverage, nuclear, among others…

What is the exact chemical composition and purity level of the metal powder?

For critical industries such as nuclear, food and pharma, impurities must be extremely low. You would want to know if Höganäs can guarantee traceability and compliance with industry standards such as ASTM, DIN and ISO. Another important factor is if the powder is free from contaminants that could affect corrosion resistance or sintering behaviour of the sintered filters.

Höganäs powders for sintered metal filters are available in a wide range of high-alloy compositions, typically 316L, 304L, Inconel 625…. All our powders feature a high level of lot-to-lot purity and high consistency.

Has the powder been optimised for sintered filter processes?

Höganäs’ powders are specifically engineered to ensure optimal and re-producible filter performance. With the right powder, your sintered metal filters can achieve superior performance and reliability.

プライバシー保護に関する方針

私は、ヘガネスが、私と連絡をとる目的で、私の個人データを利用することに同意します。 また、私の連絡先情報をニュースレターやその他関連情報といったマーケティング目的に使用することに同意します。 データが第三者と共有されることはありません。 また、16歳以上であることを認めます。

個人情報の取扱いに関する詳細は、弊社のプライバシー保護方針でご確認いただけます。